Features of the KOKI-2700 series of servo spin caulking machines

- forte1

Numerical control and control program

- forte2

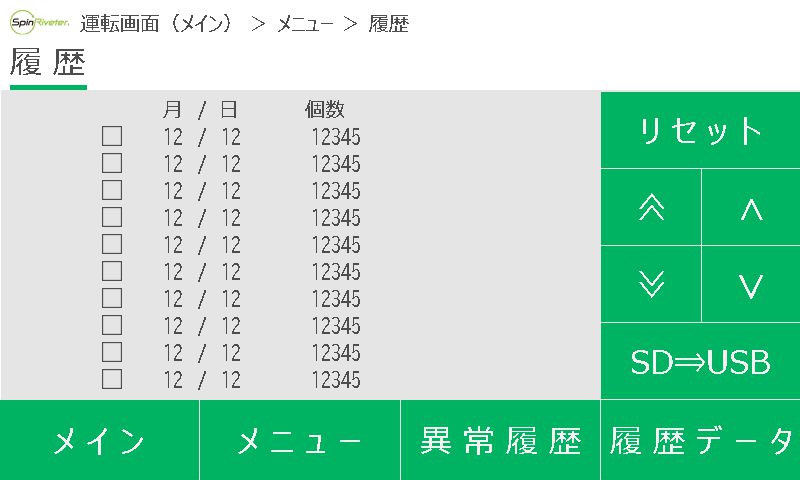

Auto-save function

(traceability measures) - forte3

Pressurization management function

- forte4

Built-in auto-riveting function

- forte5

Pass/fail judgment function

- forte6

Easy system upgrades and

customization - forte7

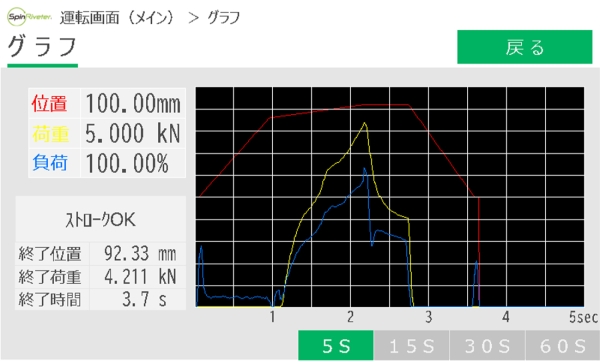

Graph display function

(optional for some models) - forte8

External communication function

(optional for some models) - forte9

Space-saving, quiet, energy-saving

- forte10

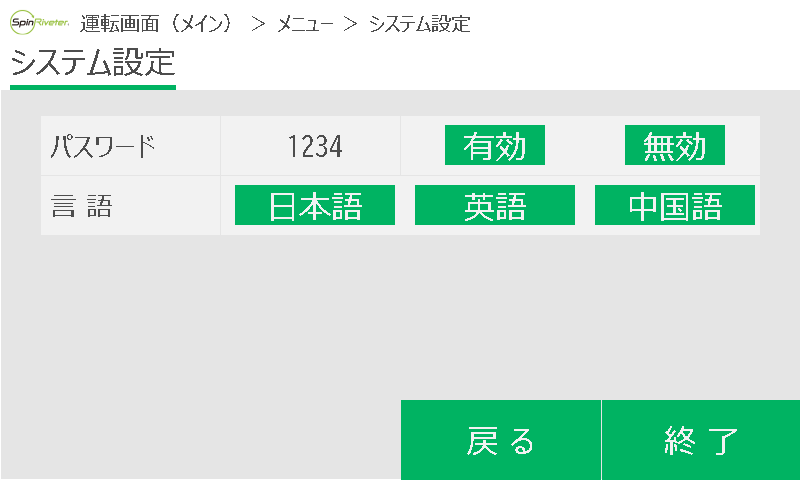

Multilingual support

(Japanese, English, Chinese)

(only on some models)

forte1

Numerical control and control program

By numerical control, anyone can easily set up the operation.

In addition, in the past, it was necessary to adjust the jig side if the setting conditions changed, but by registering the settings, past settings can be called up instantaneously, making it possible to significantly reduce the setup time.

It is possible to instantly switch between multiple settings according to the customer’s equipment specifications and products.

* The control program memory can store data of 100 models.

forte3

Pressurization management function

It is equipped with a load cell (weighting sensor) and can manage pressurization. A threshold can be set and the pressurization can be checked. If something falls outside the threshold, we will notify you with an error.

As a result, it is possible to detect the non-installation of pins (rivets) and the hardness of pins (rivets) or higher, and to prevent the contamination of defective products.

forte4

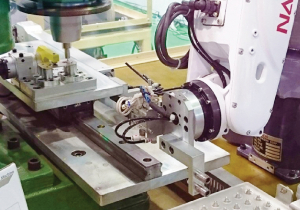

Auto riveting function

By automating computer-controlled caulking management technology, high-precision technology is realized.

At the same time, all caulking results can be inspected and recorded to prevent defects.

By constantly inspecting all caulking results, it is possible to detect defects in caulking and not to overlook abnormalities in caulking.

In addition, it is possible to reduce unnecessary movement and reduce power consumption compared to conventional products.

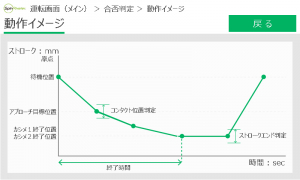

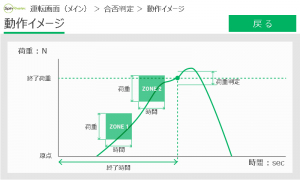

forte5

Pass/fail judgment function

The pass/fail judgment function is a function realized by electric power.

As a result, it is now possible to inspect all cases.

・Contact judgment: Determines the length of the rivet

・Stroke judgment: Determines the descending end

・Weight judgment: Determines

the state of the load at the end ・Zone judgment: Determines the state of the weight during machining

The combination of stroke and load management ensures that no abnormalities are overlooked.

The caulking result is automatically saved in the main unit for 30 days (up to 20,000 cases per day).

forte6

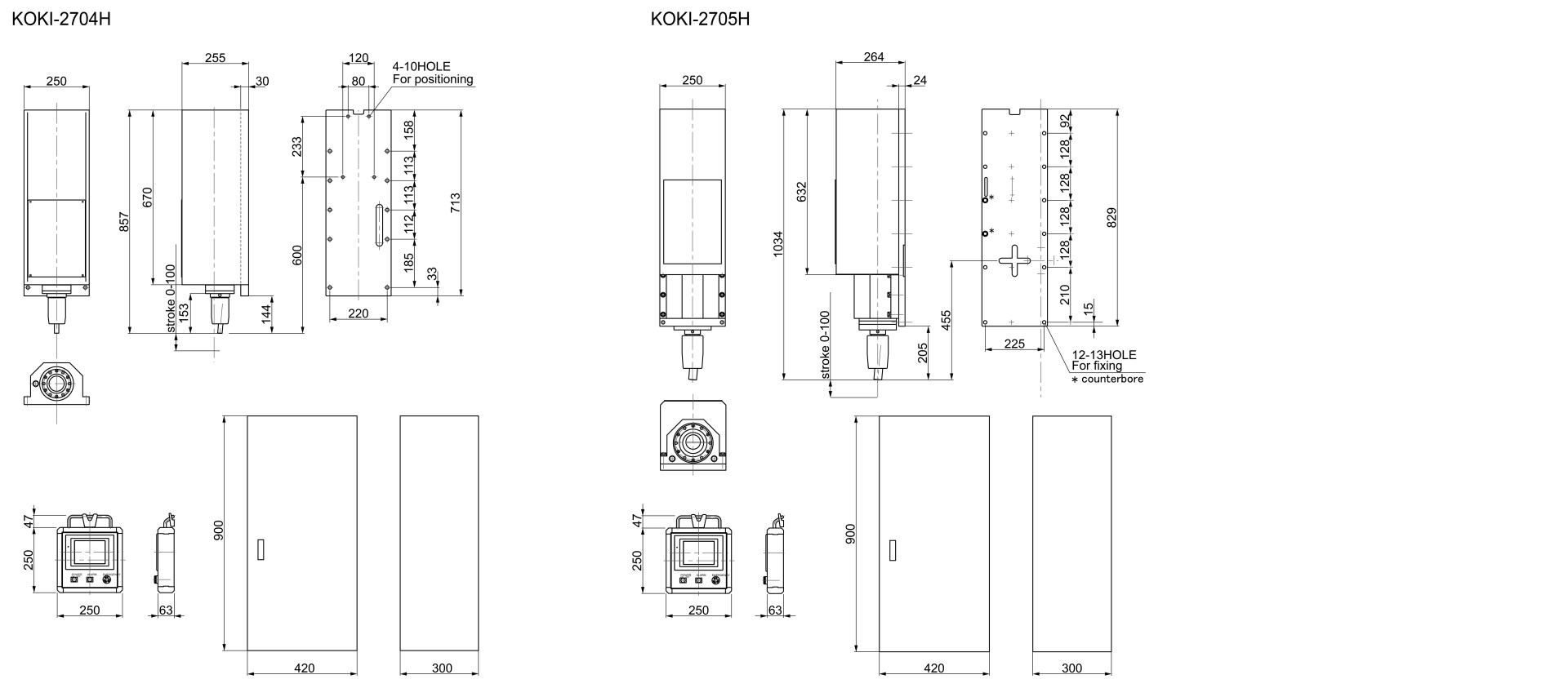

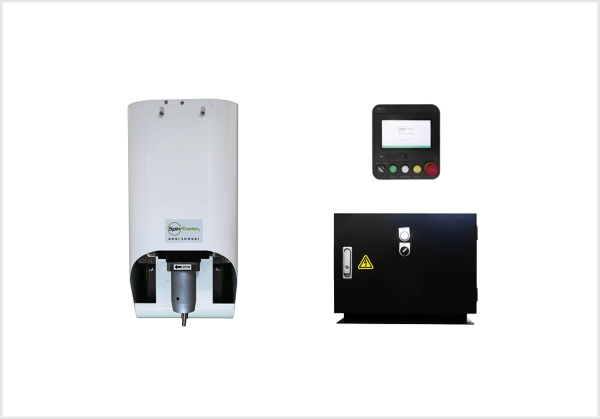

Can be disassembled into three units, making

it easy to upgrade and customize the system

A head unit type separated into three units is available.

It can be incorporated into the customer’s installation environment and equipment.

Since it is designed on the premise of customization, it is possible to respond in detail and reduce customization costs.

● 3 units

of head unit type Head unit

Control panel unit

Control panel unit

forte8

External communication function (optional for some models)

By additionally equipping the I/O unit, it is possible to operate and manage the status of the caulking machine from a connected external device.

By adding an Ethernet unit, it will be easier to fit into various installation environments.

It is possible to store and save the acquired data on a computer on the network.

forte9

Space-saving, quiet, energy-saving

Ancillary equipment such as hydraulic pumps and air compressors, which are required by conventional caulking machines, do not require servo caulking machines.

It saves space and can be installed anywhere.

Since there are no ancillary equipment, the amount of power consumption is reduced and energy saving is realized.

Since it is electric, the operation noise is very quiet, and oil does not mix in the exhaust, creating an extremely clean working environment.

forte10

Multilingual support (Japanese, English, Chinese)

(only on some models)