Screw Cylinder

More than 60 years of history and know-how, screw design

Are you only focused on the functions of the molding machine? The key point, it is the plasticizing part

In order to stably mold high-quality products, a screw that matches the characteristics of the resin used is required.

The kneading effect is improved by designing it according to the raw materials.

At Japan Oil Machinery, we will consider various screw designs and help you find clues to solve problems.

If you are worried about these problems, please contact us!

◆ Dry color masterbatch dispersion is not working well…

◆ Product properties deteriorate due to lack of kneading…

◆ Color change and resin change do not go smoothly

◆ I want a screw design for a new resin

◆ Burn and discoloration due to heat generation

◆ Contamination and sunspots occur

◆ I want to do more mixing

◆ Troubled by surging

◆ I want to mix 2 or 3 types of raw materials sufficiently.

Points for choosing screws

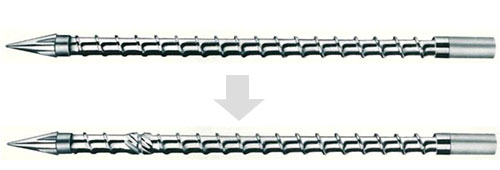

POINT 1 Improve the mixing effect with a design that matches the raw materials!

- The screw design has been changed to improve the compounding effect.

- We will help you mold with MB and dry color.

The dispersion and mixing effect will increase without changing the L/D!

By improving the general full-flight screw, the dispersion and compounding performance is improved.

POINT 2 Wear and corrosion resistance measures

In addition to wear and tear due to long-term use, screw cylinders also experience wear and tear due to composite materials.

We can choose the steel that matches your purpose.

*Please contact us for repairs.

POINT 3 Do you use screws that match the molded products?

We will design screw cylinders according to the shot volume.

Please contact us once.