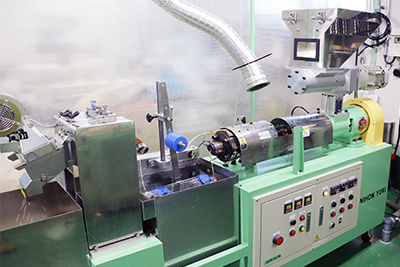

Repellet Machine

SR Ruder Bambi

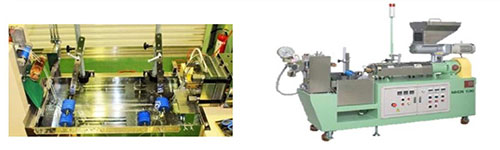

It was manufactured to recycle the pulverized material of the spool runner generated in the molding plant into recycled pellets

Since it is a recycled pellet equivalent to virgin pellets, it reduces costs, reduces molding defects, and protects the environment!

This equipment is packed with advantages over existing technologies and originality that has never been seen before. In addition, you can select the model according to the required processing capacity (kg/h).

SR Ruder Bambi operation example

Convert surplus wood in the factory into recycled pellets in-house!

- It can be used to make recycled pellets at the optimal temperature without damaging the physical properties of the resin near the molding machine.

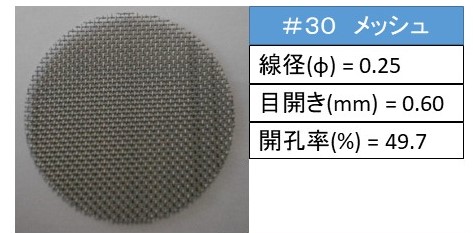

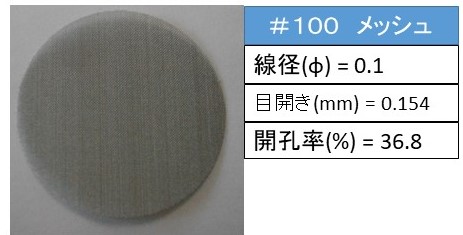

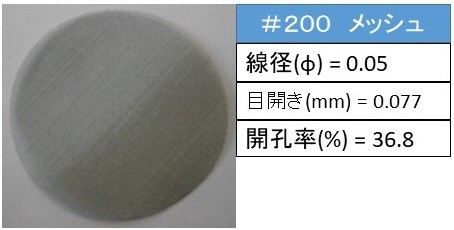

- We use a combination of 30~250 mesh screens, so there is no risk of foreign matter contamination.

- Compact type that can be installed anywhere. We have models with an hourly output of 3~32 kg.

Easy to self-produce small quantities of colored pellets

- The SR Ruder Bambi is also suitable for in-house production of colored pellets in the required quantities when needed.

What is Recycled Pellet? Why Recycled Pellet?

Why not use crushed materials as they are, but make them into pellets?

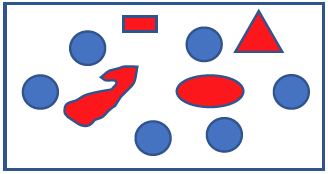

Diagram by virgin material (V material), crushed material (F material), and repellet material (R material)

[V material + F material]

(The higher the mixing ratio of F materials, the more unstable it becomes.)

[V material only]

[V material + R material]

If you use the crushed material as it is…

- Due to uneven size, poor bite causes lightweight variability

- Powder is produced when crushed. If you use it directly, the site environment is not good.

- The powder receives heat first and generates burns, carbide foreign matter, and decomposition gas.

- Grains larger than virgin pellets are not melted due to lack of heat

- This can cause molding defects

For glass fiber reinforced

If the size of the crushed material is matched to the size of the virgin pellet (φ3 x 3 mm in length), the crushing shape needs to be reduced, and the strength will be reduced because the glass fibers will break.

If you repel it with SR Ruder Bambi…

- There is no need to grind the spool runner into small pieces. Coarse grinding is fine

- Glass fibers are not easy to break, so they can maintain their strength

- You can increase the proportion of recycled materials used

- The screw design is unique, so it can be processed at low temperatures.

- There is almost no material degradation due to heat history, and the physical properties are similar to those of virgin pellets

- The pellet shape can be changed arbitrarily, so it can be the same size as the virgin pellets

- Molding defects improved. It can be molded in the same way as virgin pellets alone

Features of SR Ruder Bambi

POINT 1 Space saving

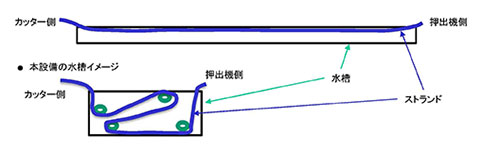

The unique submersible roller arrangement allows for efficient cooling of strands by cooling not only horizontally but also in the height direction.

The extrusion part, water tank section, and cutter part are integrated, and the total length is *3.2m (*according to the SRV-H3000 machine), making it a very compact and space-saving facility.

Since it comes with casters, there is no need to level it up.

Bambi aquarium image

POINT 2 Screw Design

The SR Ruder Bambi is a recycled pellet equipment developed using its screw design know-how.

By using the best screw design for the material, it is possible to produce recycled pellets that are comparable to virgin pellets.

In addition, since it can be processed at low temperatures, the deterioration of physical properties can be minimized, and the mixing ratio of recycled materials can be increased.

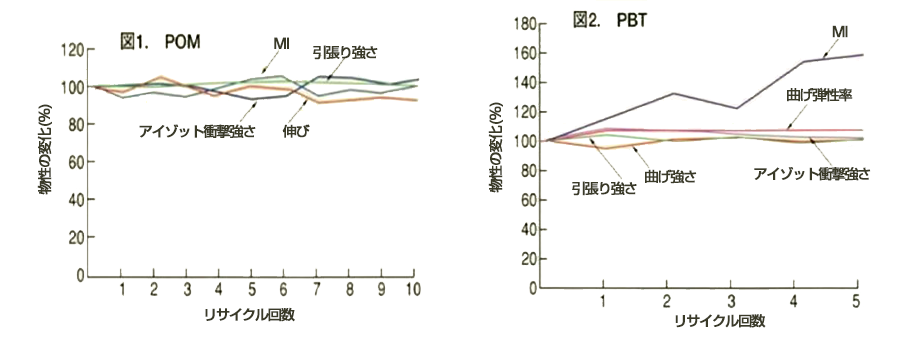

Comparison of physical property deterioration

■In the case of non-reinforced grades

Polyacetal (10 regenerations, Fig. 1), PBT (5 reproductions, Fig. 2). In either case, there was no significant change in physical properties, and no deterioration was observed.

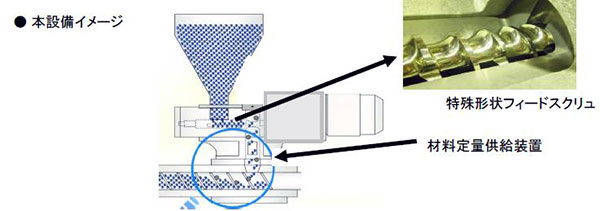

POINT3 Metering Equipment

Equipped with material quantitative feeding device. It has a built-in specially shaped feedscrew.

Even if there is a miscut in the crushed material, it can be crushed. It also reduces the generation of powder.

By supplying ingredients in a quantitative manner, the malfunction of biting into the main screw is eliminated.

It can be processed stably.

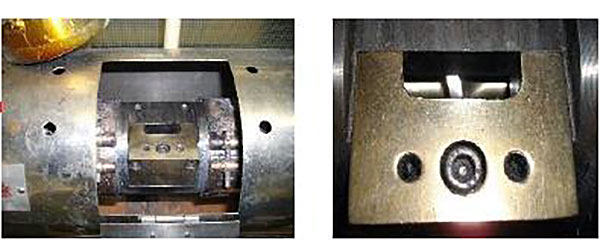

POINT 4 Vented plasticizing

There is a hole called a vent in the center of the cylinder to degas the water.

The deterioration of physical properties is suppressed, and processing is possible without pre-drying.

No drying electricity bill or dryer equipment required.

The screen collects foreign matter mixed with the raw material, so it is possible to produce pellets with foreign matter removed.

In addition, it also has the function of adjusting the internal pressure of the cylinder to prevent surging (unstable discharge volume), so you can choose a screen with a mesh that matches the viscosity of the resin.

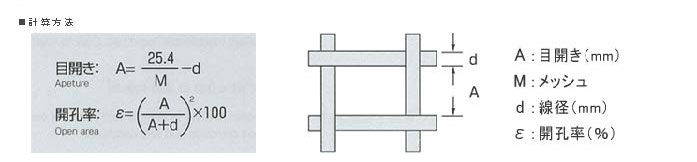

Dimensions

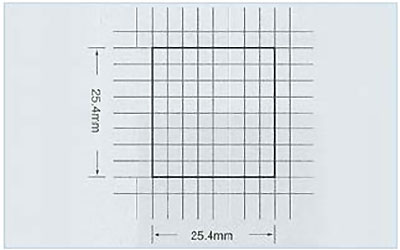

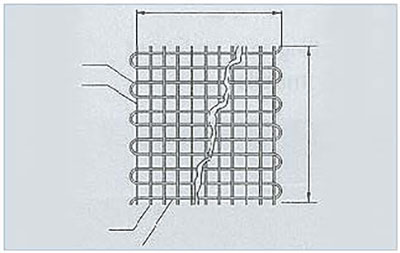

It refers to the number of eyes between vertical and horizontal lines of 25.4 mm (inches), and is expressed in units called mesh.

(Example) is 8 mesh.

1. The width dimension should be the dimension on both sides to the outside of the ear line, and the standard dimension should be 910mm/1000mm.

2. The length is expressed in the dimensions from end to end of the vertical line, and the standard (1) length is 30m. Its tolerance is +2%, -0.3%.

Specification Sheet