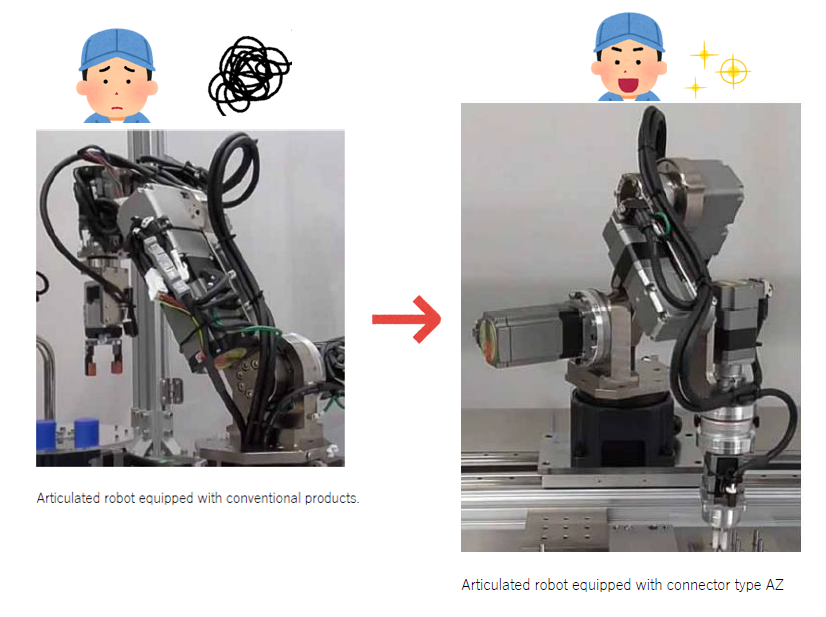

Oriental motor α(alpha) step AZ series “Connector Type”

Benefits of One Cable Technology

- Unification of Cables

- Direct Connection

- Cable Outlet Directions for Flexibility

- Faster Maintenance

- Maintains High Ingress Protection

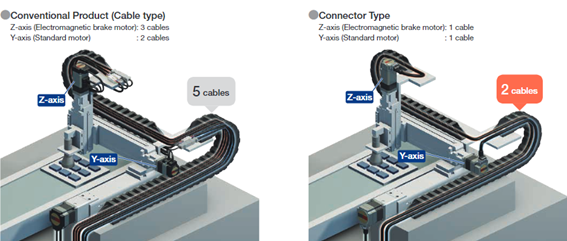

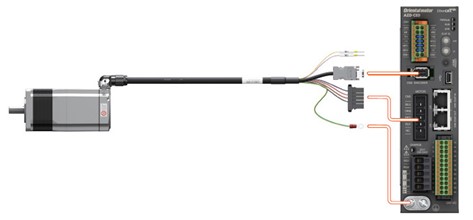

Unification of Cables

- Reduce routing work and downsize cable holder

By consolidating all the cables into one, only 1 cable is required for each motor. In the example below, we show how 5 cables for the Y and Z axes in a cartesian system are changed to 2 cables. The cable holder can be downsized as a result.

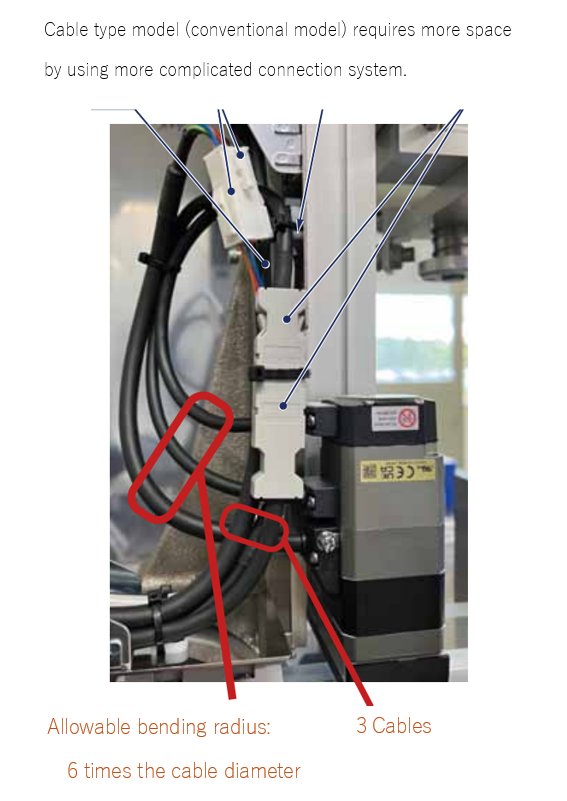

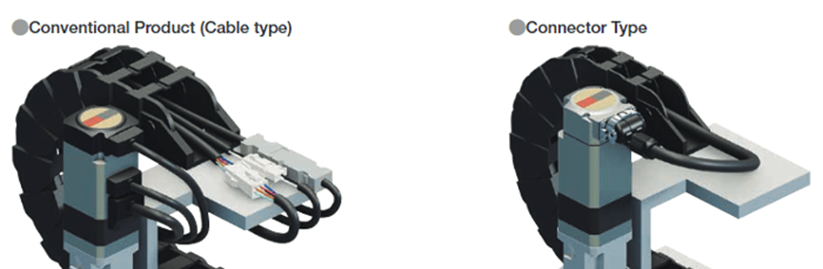

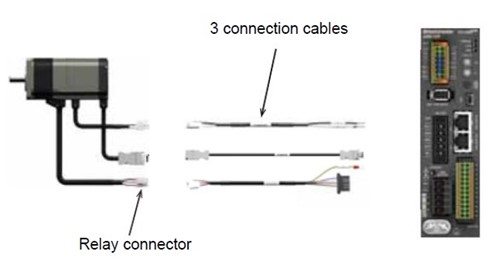

Direct Connection

- No more middle joining cables.

For the cable type motor, a connection cable is required to extend the cable more than the standard pig tail length of 300 mm. Sometimes, the electrical noise emits from the exposed connectors in between the cables can affect other machine components. The new connector type motor uses one cable technology and reduces electrical noise interference (EMI).

| Cable Type |  |

| Connector Type |  |

3 Cable Outlet Directions for Flexibility

- Select from three cable outlet directions

The connector and cable comes in 3 configurations (shaft direction, vertical direction, or opposite to output shaft direction). You must order the connection cable this way (use “F” = front, “B” = back, “V” = vertical in the cable part number ). This increases the degree of cable outlet freedom around the motor.

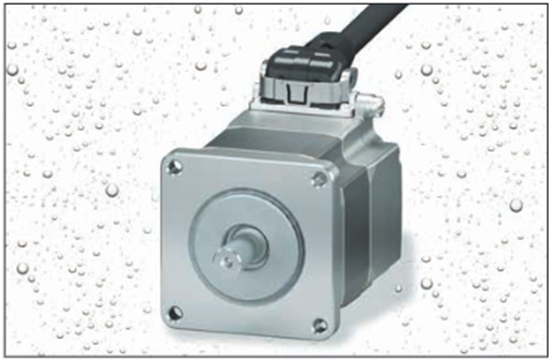

Maintains High Ingress Protection

- The new connector and cable maintain an IP66 ingress protection rating for dusty or washdown environments

Same as the cable type motor, the connector type motors maintain the IP66 rating; meaning that it’s able to handle a sprayed water jet of 100 kPa at a rate of 100 l/min for 3 minutes from all directions at a distance of 3 meters.

VIDEO

αStep AZ Series Product Family