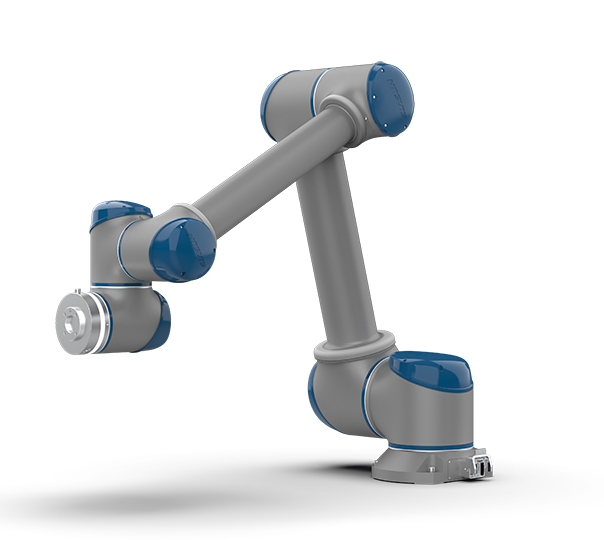

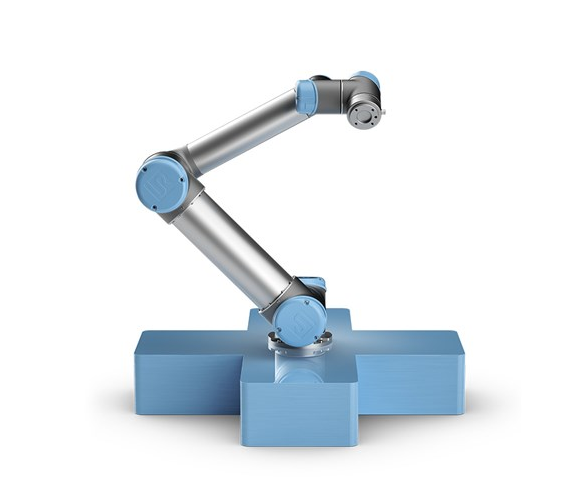

Collaborative robots

As the name suggests, robots and humans can work together on the production line, giving full play to the efficiency of robots and human intelligence. This kind of robot is not only cost-effective, but also safe and convenient, which can greatly promote the development of manufacturing enterprises [1] .

As a new type of industrial robot, collaborative robots have removed the obstacles of human-machine collaboration, allowing robots to completely get rid of the shackles of guardrails or cages, and their pioneering product performance and wide range of application fields have opened a new era for the development of industrial robots

The smart factory of the future is created by the harmonious coexistence of humans and machines, which requires robots to be able to cooperate with humans and complete different tasks with humans. This includes not only the completion of traditional tasks that “people can’t do, people don’t want to do, and people can’t do well”, but also complex tasks that can reduce human labor intensity and improve the quality of human life. Because of this, human-robot collaboration can be regarded as a necessary attribute of new industrial robots

Human-robot collaboration has brought fundamental changes to the industrial production and manufacturing of the factory of the future, with decisive and important advantages [2] :

(1) Maximum flexibility in the production process [2] .

(2) Reducing the burden on employees by undertaking manual processes that were previously unautomated and not ergonomic [2] .

(3) Reduce the risk of injury and infection, such as using special human-robot collaborative grippers [2] .

(4) Repeatable processes are completed with high quality without investment depending on type or workpiece [2] .

(5) Adopt a built-in sensing system to improve productivity and equipment complexity [2] .

Based on the advantages of human-robot collaboration, in line with market demand, more flexible collaborative robots have become a feasible solution to undertake assembly and extraction work. It can maximize the advantages of humans and robots, so that robots can better cooperate with workers and adapt to a wider range of work challenges [2] .

Key features:

The main features of cobots are [ :

1. Lightweight

Make the robot easier to control and improve safety.

2. Friendliness

Ensure that the surface and joints of the robot are smooth and flat, with no sharp corners or gaps that can easily pinch the operator [3] .

3. Perceptual ability

Perceive the surrounding environment and change its own behavior according to changes in the environment [3] .

4. Human-machine collaboration

It has a sensitive force feedback characteristic, which stops immediately when the set force is reached, and eliminates the need for protective barriers after risk assessment, allowing humans and robots to work together [3] .

5. Easy programming

It is very easy for some ordinary operators and people with non-technical backgrounds to program and debug [3] .

Human-robot collaboration

The development of intelligent manufacturing is inseparable from robots. The development of intelligent robots is the only way to build an intelligent manufacturing equipment platform and improve the automation and intelligence level of the manufacturing process [4] .

In 1959, the Americans built the world’s first industrial robot, and since then, robots have gradually become popular in the industrial field. With the continuous progress of science and technology, especially the advent of Industry 3.0, automated production lines with extensive use of industrial robots have become the core equipment of the manufacturing industry [4].

However, in the era of intelligent manufacturing, in order to respond to the growing demand of consumers for customized products, smart factories need to make full use of existing resources in a limited space, build flexible, safe, and rapidly changing intelligent production lines, in order to adapt to the production of new products, replace production lines, shorten product manufacturing time, and need flexible and fast production units to meet these needs, and improve the production capacity and efficiency of manufacturing enterprises, and reduce costs. Therefore, intelligent robots will become the most important hardware equipment in intelligent manufacturing systems. In a sense, the comprehensive upgrade of intelligent robots is an important part of the new round of industrial revolution. However, in some product areas and production lines, manual operations are still indispensable, such as assembling high-precision components and intensive labor that requires a high degree of flexibility. In these cases, collaborative robots will play an increasing role [4] .

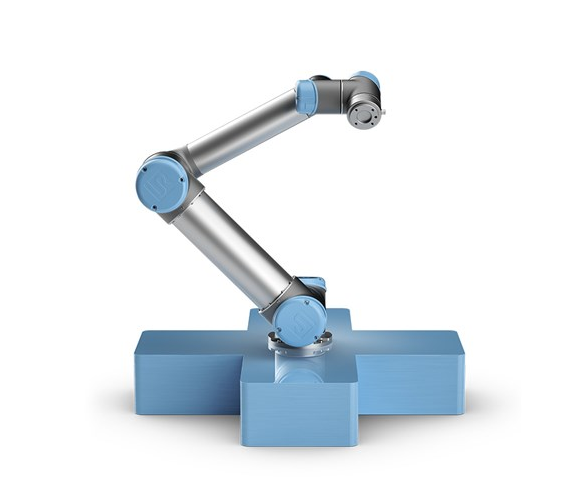

The so-called human-robot collaboration is in which robots are engaged in highly accurate and repetitive work processes, and workers are assisted in creative work. The use of human-machine collaborative robots has made the production wiring and configuration of enterprises gain greater flexibility space, and also improve the product yield rate. Human-robot collaboration can be done in the form of a division of labor between humans and machines, or humans and machines working together [4].

Not only that, the development of intelligent manufacturing requires greater changes in the relationship between humans and machines. Humans and machines must be able to understand, perceive, and help each other in order to be able to coordinate closely in a space, interact naturally, and ensure each other’s safety [4] .

In the era of transformation and upgrading of the manufacturing industry, intelligent robots will become more and more deeply rooted in our work and life. If the R&D and promotion of intelligent robots are neglected, the entire “Made in China 2025” development strategy may be shaken from the foundation. The human-machine collaboration mode of people and equipment and machines working together can improve enterprise efficiency, strengthen quality control, enhance production flexibility, reduce the cost of logistics lines, and bring manufacturing enterprises closer to the market. Robots are the supporting equipment for intelligent manufacturing, and human-robot collaboration will become the essential feature of the next generation of robots [4].

Research status and development trends

The human-machine collaboration system has undergone a process of accumulation and gradual development, especially in the last 30 years, with the continuous development of artificial intelligence, the human-machine collaboration system has also entered the “fast lane” of development. After decades of development, the human-machine collaboration system has achieved good application results and economic benefits in many fields. The following is illustrated by taking the newly emerged collaborative expert system and computer-integrated manufacturing system as examples.

Collaborative expert system

Most of the expert systems that currently exist (computers, etc.) are within a defined area of expertise, and they are an “expert”, but once they are outside of a specific area of expertise, the expert system may not work. The collaborative expert system has been gradually developed in order to overcome the limitations of the general expert system. In the mid-80s of the 20th century, with the application of common sense reasoning and fuzzy theory and the maturity of deep knowledge representation technology, the expert system began to transform into a multi-level comprehensive type of multi-knowledge representation and multi-reasoning machine. The collaborative expert system is based on correcting the simplification of the traditional expert system for solving complex problems, and begins to pursue in-depth explanation and reasoning, and the realization principle is technical complementarity, starting from the combination of simple knowledge representation and reasoning methods, and gradually developing to the synthesis of the structure of the expert system.

The system can integrate a number of sub-expert systems in similar fields or multiple aspects of a field to work together to solve a broader problem. When studying complex problems, the identified total task can be broken down into several sub-tasks, which are completed by several expert systems. Each expert system gives full play to its own strengths, solves a problem and then collaborates with subsystems to ensure that the reasoning of the expert system is more comprehensive, accurate and reliable. The process of collaborative expert system collaborative problem solving can be divided into four stages: problem division, sub-problem allocation, core inter-problem solution and synthesis of reasoning results. These four phases are recursive, and for non-core subproblems, the process needs to be maintained, and it may be repeated “recursion-resurgence” until the problem is resolved. The synergistic expert system is widely used in the medical field, and today’s organic swelling diseases include a variety of lung cancer, gastric cancer, liver cancer, esophageal cancer, nasopharyngeal cancer, leukemia, etc. If an expert system were to be developed for each type of cancer, it would only be possible to diagnose one type of cancer: this would be a clear waste of manpower and resources. Experts have developed collaborative expert systems such as “Doctor Watson” and “Top Ten Common Malignant Tumor Diagnosis and Treatment Expert System”, which can well assist doctors in diagnosing various cancers and giving corresponding treatment plans. In addition, the collaborative expert system is also widely used in medical diagnosis, weather forecasting, chemical engineering, financial decision-making, geological exploration, speech recognition, image processing and other fields.

Computer-integrated manufacturing systems

The human-machine collaboration system has also been applied in the modern manufacturing industry and has achieved good results. In modern manufacturing, computer-integrated manufacturing systems are developing rapidly. The computer integrated manufacturing system was first proposed by the American scholar Joseph Harrington in 1973, which refers to the comprehensive use of modern management technology, manufacturing technology, information technology, system engineering technology, etc., to organically integrate and optimize the operation of man, machine (computer, production and control equipment, etc.) in the whole process of enterprise production. In such a system, humans and machines work together to perform their own duties. People are mainly engaged in perception, reasoning, decision-making, creativity, etc.; Machines, on the other hand, play a role in the implementation and control of the production process, or perform tasks that cannot be done by people due to physical or psychological factors. In recent decades, especially since 1990, many chemical, steel and machinery manufacturing enterprises in the United States, Western Europe, Japan, South Korea and China have adopted computer-integrated manufacturing systems. According to the survey, after the adoption of computer integrated manufacturing system, a number of enterprises have significantly improved production efficiency, product quality and equipment utilization, and significantly reduced the amount of engineering design, shortened the production cycle, and achieved good economic benefits. The task completion process of collaborative robots in industrial production is illustrated as an example. Designed to assist humans and work with them without the need for isolation with safety fences, cobots are collaborative, safe, fast learning, adaptable, efficient and cost-effective. According to relevant foreign statistics, in 2014, the market size of collaborative robots was about 100 million US dollars, and it is currently growing at an annual rate of 50%. It is expected that by 2020, robots will form a new situation of “human-machine integration” [5] .

Human production has experienced all-manual labor, to semi-automatic, fully automatic and other production modes, and the future will inevitably enter the era of collaboration between humans and robots, and become a normal mode of work. Today, robots may only be used upstream and downstream such as loading and unloading the production line, and in the assembly process, manual assembly is used, and the conveyor belt system is used to pursue lean production of units. In the future, in the production line, humans and robots will be mixed and matched, and cobots will use multi-functional claws and pliers, using guided and efficient programming, to improve the cost competitiveness of the entire assembly system. Multi-degree-of-freedom kinematics manipulators work with humans, and their compact motion does not disturb the work of workers. In the future of collaborative robots, in terms of man-machine work distribution, simple and repetitive, labor-intensive labor will be left to robots, and complex intellectual labor will be left to human beings themselves, and collaborative robots are breaking the shackles of traditional robots, and a storm of manufacturing machine substitution may arise in the pursuit of low price, high efficiency, safety and production diversification today [5] .

Although the current human-machine collaboration system has been widely used in all aspects of production and life, it has changed or is changing the way human beings perceive the world and transform the world. However, there are relatively few studies on collaborative decision-making and effective task allocation, and human-machine collaborative systems also face technical difficulties and social problems in knowledge acquisition. There is a certain correlation between grasping the development trend of human-machine collaborative systems and understanding of artificial intelligence. The development of human-machine collaborative systems has well realized or is in the process of realizing weak artificial intelligence with fruitful results, such as the current various expert systems. In many human-computer collaboration systems, computers have done a good job of computing and reasoning tasks assigned and assigned by people, freeing people’s hands and brains to a large extent.

Strong AI still faces many philosophical and practical problems, but AI experts are still actively trying to explore and try to break through various limitations. With the development of strong artificial intelligence, the human-machine reasoning system will continue to develop, which will better replace people’s work and further liberate people from heavy work.

(1) Friendly cooperation between man and machine. Automated processes still require people, and humans are part of the solution, and existing technologies cannot be fully automated. A complete human-robot collaboration system with simpler programming means that the plant does not require many engineering resources.

(2) More effective and better. Automation with minimal safety risks and tight workspace makes it easier for factories to use existing sites for efficient production, and collaborative assembly lines that mix and match humans and machines make production faster and more efficient.

(3) Higher quality, less waste. Humans and robots work together to surpass the accuracy and speed of human work, resulting in higher product quality and less waste.

(4) Simplified programming techniques. Leading the way in programming technology, which is different from traditional complexity programming. Anyone can master it with no special training or programming skills