- High Responsiveness and Stability: Model adaptive control ensures high response and stable operation.

- Multi-Mode Control: Supports position, speed, and torque control modes.

- Advanced Vibration Suppression: Minimizes machine vibration for enhanced precision.

- High-Resolution Encoder: 131072 pulses/rev for accurate positioning feedback.

- Flexible Communication: USB and RS-422/RS-485 interfaces for easy integration.

- Protective Functions: Overcurrent, regenerative overvoltage, and overload shut-off for safe operation.

-

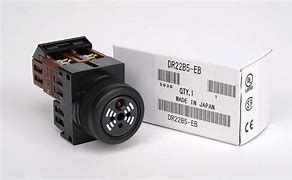

Servo Amplifier Model MR-J3- 10A 20A 40A 60A 70A 100A 200AN 350A 500A 700A 11KA 15KA 22KA 10A1 20A1 40A1 Mitsubishi Servo Drive MR-J3 S S S S S S S S S S S – – S S S Voltage/Frequency (*1, *2) 3-phase 200 to 230VAC 50/60Hz or1-phase 200 to 230VAC 50/60Hz (*10) 3-phase 200 to 230VAC 50/60Hz 1-phase 100 to 120VAC 50/60Hz Permissible Voltage Fluctuation For 3-phase 200 to 230VAC: 3-phase 170 to 253VACFor 1-phase 200 to 230VAC: 1-phase 170 to 253VAC 3-phase 170 to 253VAC 1-phase 85 to 132VAC Permissible Frequency Fluctuation ±5% maximum Voltage/Frequency 1-phase 200 to 230VAC 50/60Hz (*10) 1-phase 200 to 230VAC 50/60Hz 1-phase 100 to 120VAC 50/60Hz Permissible Voltage Fluctuation 1-phase 170 to 253VAC 1-phase 85 to 132VAC Permissible Frequency Fluctuation ±5% maximum Power Consumption (W) 30 45 30 Interface Power Supply 24VDC ±10% (required current capacity: 300mA (*7)) Built-in Regenerative Resistor – 10 10 10 20 20 100 100 130 170 – – – – 10 10 External Regenerative Resistor (Standard Accessory) (*5, *6) – – – – – – – – – – 500(800) 850(1300) 850(1300) – – – Control System Sine-wave PWM control/current control system Dynamic Brake Built-in (*8, *13) External option Built-in (*8, *13) Safety Features Overcurrent shutdown, regeneration overvoltage shutdown, overload shutdown (electronic thermal), Servo Motor overheat protection, encoder fault protection, regeneration fault protection, undervoltage/sudden power outage protection, overspeed protection, excess error protection Maximum Input Pulse Frequency 1Mpps (when using differential receiver), 200kpps (when using open collector), (4Mpps) (*11) Positioning Feedback Pulse Resolution per encoder/Servo Motor rotation: 262144 p/rev Command Pulse Multiple Electronic gear A/B multiple, A: 1 to 1048576, B: 1 to 1048576, 1/10 < A/B < 2000 Positioning Complete Width Setting 0 to ±10000 pulses (command pulse unit) Excess Error ±3 rotations Torque Limit Set by parameters or external analog input (0 to +10VDC/maximum torque) Speed Control ModeSpeed Control Range Analog speed command 1:2000, internal speed command 1:5000 Analog Speed Command Input 0 to ±10VDC/rated speed (possible to change the speed in 10V using the parameter No. PC12.) (*12) Speed Fluctuation Rate ±0.01% maximum (load fluctuation 0 to 100%) 0% (power fluctuation ±10%) ±0.2% maximum (ambient temperature 25°C±10°C (59°F to 95°F)), when using analog speed command Torque Limit Set by parameters or external analog input (0 to +10VDC/maximum torque) (*12) Torque Control ModeAnalog Torque Command Input 0 to ±8VDC/maximum torque (input impedance 10 to 12kΩ) (*12) Speed Limit Set by parameters or external analog input (0 to ±10VDC/rated speed) Structure Self-cooling open (IP00) Fan cooling open (IP00) Self-cooling open (IP00) Ambient Temperature (*6, *9) 0 to 55°C (32 to 131°F) (non-freezing), storage: -20 to 65°C (-4 to 149°F) (non-freezing) Ambient Humidity 90% RH maximum (non-condensing), storage: 90% RH maximum (non-condensing) Atmosphere Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust Elevation 1000m or less above sea level Vibration 5.9m/s² maximum Weight kg (lb) 0.8(1.8) 0.8(1.8) 1.0(2.2) 1.0(2.2) 1.4(3.1) 1.4(3.1) 2.1(4.6) 2.3(5.1) 4.6(10) 6.2(14) 18(40) 18(40) 19(42)

0865 735 110