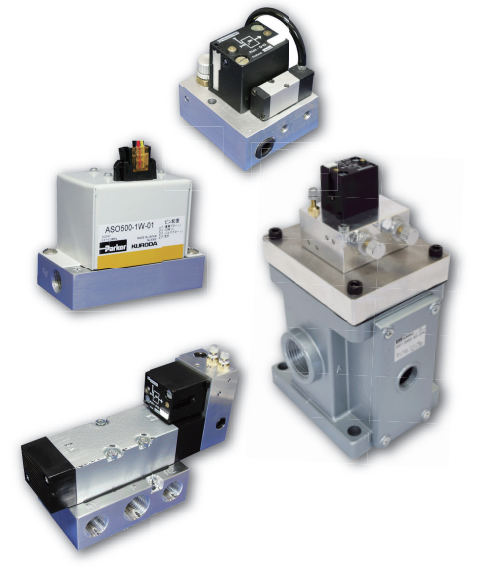

TAIYO Pneumatic equipment (air saving unit) ASV series

|

air saving unit ASV series Easy power saving and environmental measures! Significant reduction in factory air consumption |

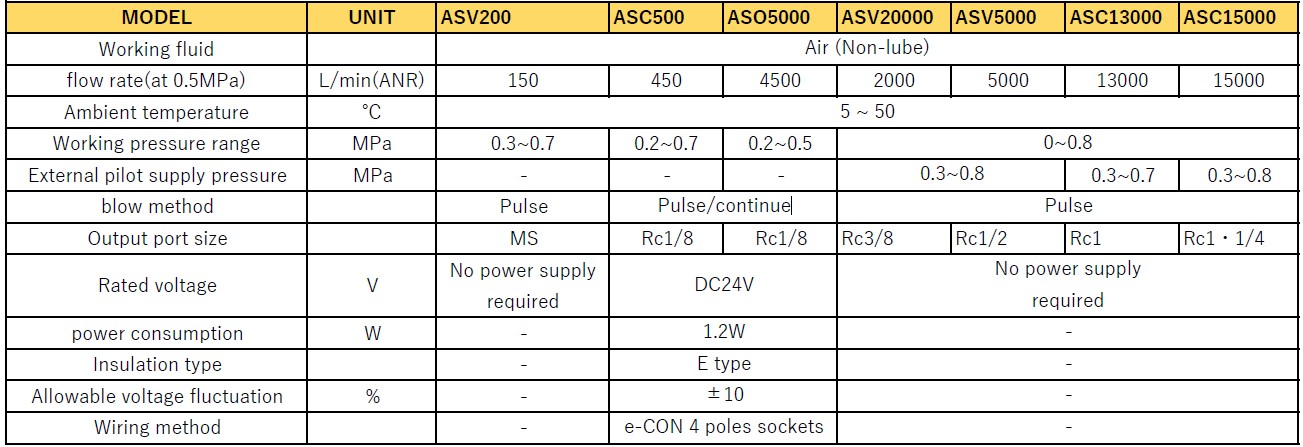

■ SPEC

| Automotive parts assembly line Air blow before assembly | |||

| Content | If foreign matter adheres to the work transport pallet, it may lead to product defects. cause. Remove foreign matter with an air blow. |

||

| Customer Reason for choosing |

Since pulse blowing can be performed without electrical work, installation is easy. The amount of compressed air used can be greatly reduced. |

||

| Case study | Ensure that there is no foreign matter adhering to the surface of the assembly pallet or the assembly surface of the workpiece.Therefore, perform an air blow just before assembly. | ||

| effect | ▲Before installation Compressed air consumption per year 53,637 N㎥ (CO2 emissions 3.38 tons) |

▲After installation Compressed air consumption per year 26,819 N㎥ (CO2 emissions 1.69 tons) |

|

| Annual reduction effect (Reference air unit price 2.4 yen/㎥) = ¥64,300/year |

Reduction rate = 50% |

return on investment = about 10 months |

|