Welding of Aluminum

Effective also

for copper alloys

Considering the characteristics of aluminum where rapid heat diffusion is generated, more reliable weld penetration has been achieved by activating precision inverter control to slightly generate the after-arc phenomenon (remaining heat) after melting.

PULSING

Achieving the zero base current, thereby ensuring stable welding for longer distance.

For general pulsed arc welding, the base current exists between peaks, and continued heating causes shrinkage and deformation. With our Model V02, smooth, even beads can be formed by reducing the peak-to-peak current to zero.

SINGLE・DOUBLE WIRE

Two setting modes selectable according to welding methods

SINGLE WIRE MODE

Speed-oriented Single Wire mode to directly weld the handheld wire.

DOUBLE WIRE MODE

Double Wire mode to reliably weld several temporarily fixed wires.

You can choose either one of the two welding modes according to the degree of difficulty of the work or the level of skill.

Combined use of

TIG & RES.

Easy calling up of

the adequate setup

Presetting

the favorite setups

TIG welding and resistance welding are integrated into a single chassis, which enables covering tentative fixing work up to finish work with a single V02 machine.

Adequate welding setups (current and time) corresponding to two vertexes, depth side corners, three vertexes, and flat surfaces are stored.

The conditions fixed by workers are saved under the Save mode and the conditions can be called up easily next time.

WIRE SIZE

From ultra-fine welding material to buildup welding

Use of φ0.1 ㎜ wire size

Use of φ0.4 ㎜ wire size

Use of φ2.0 ㎜ wire size

You can choose a wire size from φ0.1 mm to φ2.0 mm, thereby handling a broad range of ultrafine pinpoint welding up to buildup welding of wide flat surfaces.

Wiring diagram

Responding to skills of experienced

welder, while supporting beginners

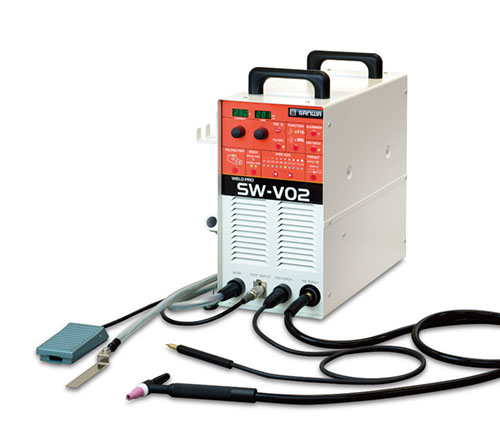

Main unit

Wiring diagram

The WELD PRO SW-V Series models have evolved where the functions of TIG welding that enables ultra-high precision and resistance welding that is convenient for tentative fixing and simple repair are integrated into one welding machine. The series models feature the more user-friendly Weld Navigation that leads precision welding to a higher dimension, and the Aluminium Mode that enables precision welding of aluminum that is currently assumed to be difficult. Furthermore, the varieties of functions that assist the various scenes of welding support beginning welders, and high-level performance that has been accumulated after each version upgrade responds to the skills of experienced welders. Why don’t you physically feel the sophistication and the evolution that open up a new era in ultra precision padding welding machines?

Configuration

Broad Application Range

Tool box

Foot switch

Gas hose

Output cord for resistance welding : for φ13㎜

Hand piece for resistance welding : for φ2 / 3㎜

Output cord for resistance welding : for φ18㎜用

Output cord for resistance welding : for φ5㎜用

Silver tungsten electrode for resistance welding

Torch cord for TIG welding

Tungsten electrode for TIG welding φ1.6㎜

Work cord

Metal cutter

Aramid gloves

A gas pressure adjuster shall be attached to products for domestic use only.

Either 4 or 5 shall be attached as standard configuration.

■Plastic mold ■Die casting mold ■Press mold

■Glass mold ■Blow mold ■Rubber mold

■Copper alloy mold etc…

Diverse Purposes

Parting line part, slide edge areas where shocks are applied

Pin-gate areas, tunnel-gate areas

Repair of ejector-holes, thin edge areas

Smoothing pinholes and surface depressions after argon welding

Padding after electric discharge machining, nitriding,

and tufftride processing

Specifications

Input Voltage

Reted Output Current

Maximum Voltage of No-Load

Output Current

Welding Time

Repetition Period

Control Method

Cooling Method

Dimensions

Weight

Single Phase

AC200/230V 50/60Hz

10.4 kVA(Peak value)

2.8 kVA(Average value)

approx.76V(TIG welding)

Resistance welding/30~750 A

TIG welding/2~250 A

Resistance welding/1~30ms

TIG welding/1~600ms

Resistance welding/400ms

TIG welding/0.1~2.0s

Inverter Method

Forced air cooling

W 204 X D 425 X H 390 (mm)

23.8kg