Vent Unit

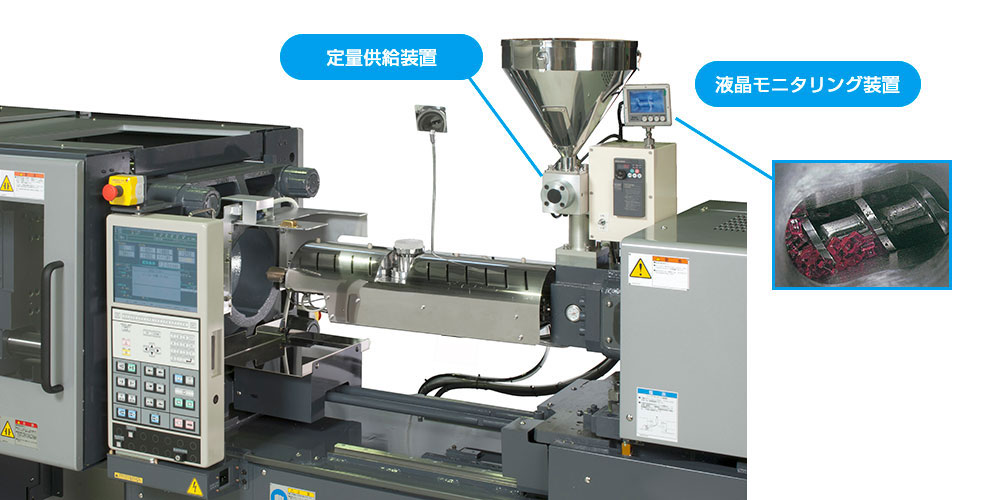

Vented plasticizing unit

Prevents vent-up and speeds up resin replacement.

The vented injection molding method provides the solid answer.

We will renovate the plasticizing part of your non-vented injection molding machine (up to 10t~1200t) to a vented type.

History of Vented Molding Machine

Injection molding machines in Japan started as plunger type around 1950.

Later, with the rapid expansion of the types of raw materials, a wide variety of plastic products became available, and the inline screw type was developed, which is now the mainstream.

Why didn’t vent injection molding machines become popular?

With the advent of composite resins with fillers and resins that require drying, < vent-type injection molding machines that do not require pre-drying have been developed and attracted attention for >a while.

However, due to the resin erupting from the vent opening, changing color, and taking time to change the resin, it gradually disappeared, and today it has become the main generation that does not know the venting method.

The Resurgence of Vented Injection Molding Machines

Our vented plasticizing units have solved various problems that were once bottlenecks through their unique screw design.

In addition, taking advantage of the original characteristics of “no drying process”, “saving electricity costs”, and “reducing the gas entering the mold and reducing the product defect rate”, the vented injection molding machine has begun to take the road of revival as a low-cost, energy-saving injection molding.

How Vented Injection Molding Machine Works

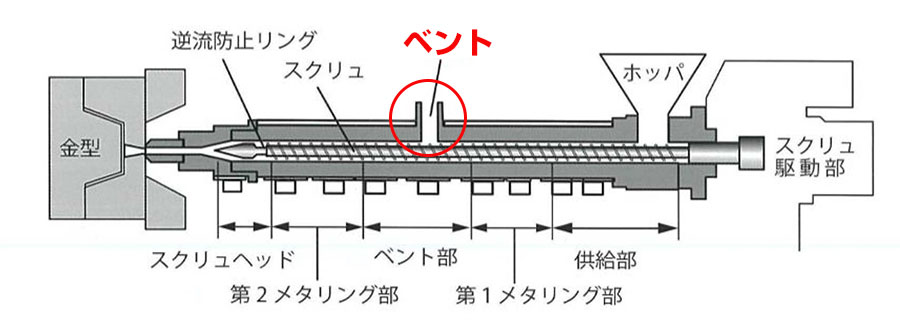

The vent injection molding machine has a hole called a vent in the middle of the cylinder, as shown in the figure below.

This is an injection molding machine that can discharge gases and moisture generated when resin melts through the vent part.

Advantages of vented molding machines

Molding while degassing gas and moisture has the following advantages.

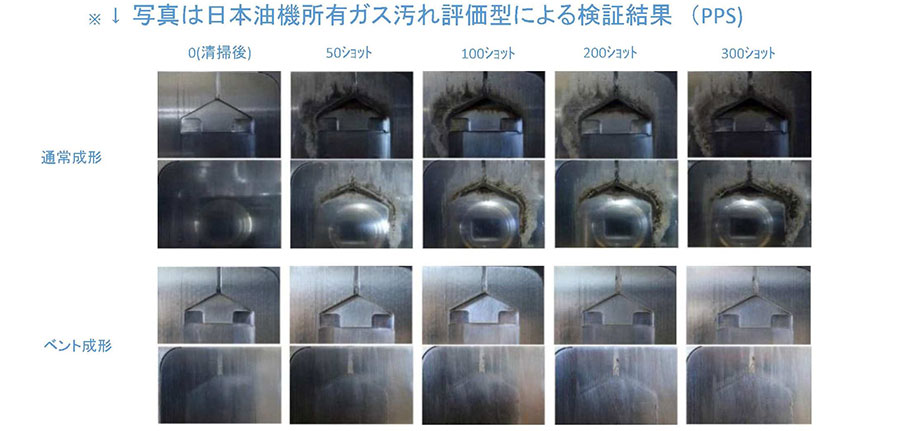

Advantage 1 Gas reduction

- Reduced molding defect rate by gas

- Reduced gas (MD) on the mold

Advantage 2 Pre-drying without molding

- No dryer capital investment required

- No electricity bill for drying

- No setup time required for drying

- No dryer installation space required

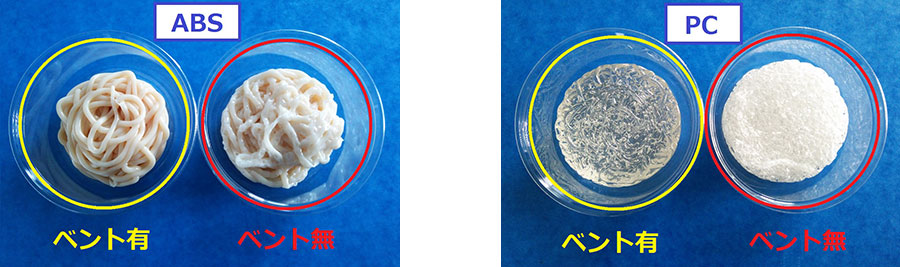

Comparison photo of purge dango and molded product appearance in non-drying molding (PC)

Is it really okay if it doesn’t dry out?

Depending on the type of resin, some resins decompose and lose strength when molded with high water absorption.

At our company, we can mold specimens with or without water absorption and compare physical properties.

*Depending on the content of the exam, there may be a fee.

*We do not evaluate physical properties.

List of molds owned

Dumbbell specimen

Flat plate (100×100 T=3)

gas-rated